New in the

world of 3D printing.

All // Announcements // Case Studies // Guides // General

July Update 2019

After many trials and tribulations, our custom wire harnesses have arrived and production is under way! Our trial production has been successfully completed and 6 new Nautilus 3D printers have joined our print farm!

Classroom 3D Printing: A Quick Guide to Printer Selection

More and more schools are adding 3D printing to their repertoire every year because of the many benefits they can offer students. They’re an opportunity for students to learn design and skills and get experience with CAD (computer-assisted design) software. Additive manufacturing (3D printing) also enables teachers to produce customized teaching aids and motivational trinkets for their students. However, the 3D printing market is very crowded and online forums are full of conflicting advice about the best printer to buy and how to implement it.

June Update 2019

Trial production of the Nautilus is officially underway! We completed assembly of the first of our six trial Nautili that will form our print farm and we’re very happy with how it turned out. The printer is looking and working great so we will begin producing parts for the final production run this week! It was awesome to build a Nautilus with all of the finalized components instead of the re-used and handmade parts we use for development. If you’ve been waiting to get your order in, now’s the time!

May Update 2019

Due to stock levels with some of our suppliers, we will not have all the parts for the Nautili in until late May, meaning it will be at least a week after that until we can start shipping Nautili. Luckily the delayed parts are not needed to begin production as they can be added at the very end. Thus we can still continue our plans to begin production as soon as possible. We will continue to allow pre-orders until production fully begins, so get your order in while you still can!

April Update 2019

We are getting ready for our trial production run of the Nautilus. Parts have begun arriving and we are getting excited to start producing Nautili. We hope to be finished with trial production by the end of April.

March Update 2019

We have officially moved!

Our new warehouse space is located in NE Portland and we share it with a number of other Portland based companies. The space we have is 10 times the size of the tiny office where the two of us developed and tested the Nautilus.

Once we are all set up, we plan to look into open houses and workshops for the local community.

Injection Molding vs. 3D Printing

These days, plastic parts are in almost every piece of hardware out there. Almost all plastic parts are injection molded; it’s a great method for producing a ton of parts without changing the design. However if production volume is small or the design changes frequently, 3D printing offers a powerful alternative that can save a lot of time and money. In fact, it is the cost savings of 3D printing that made developing the Nautilus possible to begin with! We wanted to show the power of 3D printing through a case study on one of the parts that appears on the Nautilus: a Z-Axis Gantry.

Nautilus Development - January 2019 Update

You can now reserve a place in the queue for the first round of production. We aim to begin production in March after we move into our new space (more about that below). Reservations are $150 and will guarantee you a printer from our first production run. Reservations are limited, so make sure to purchase your spot before they run out!

Nautilus Development - November 2018 Update

Beta testing for the Nautilus 3D printer is officially under way! We have sent out the first two beta units and are beginning production of a second round of three more beta units, which will be going out soon.

Nautilus Development - September 2018 Update

We had a great time sharing our new Nautilus 3D Printer prototype at the Portland Mini Maker Faire this September!

Thank you to all those who stopped by and showed their enthusiasm and support for what we are doing. It was awesome!

Nautilus Development - August 2018 Update

I was initially planning on using the Einsy Rambo by Ultimachine in conjunction with a Raspberry Pi running Octoprint, but due to the limitations of the Einsy's 8bit framework and communication issues between marlin and Octoprint I was not able to have all the features I had envisioned.

Nautilus Development - June 2018 Update

I am pretty happy with the hardware design of the printer. I have reached a point where there are no major issues and everything fits and functions properly. The front frame panel now goes top to bottom and the door is inset into this panel. This increases the rigidity of the printer. Additionally, I have opted for an all-black design in this iteration, as black printed parts are easier to produce without cosmetic defects I decided that I want the acrylic to match the printed parts, so a matte black acrylic will be used.

Nautilus Development - May 2018 Update

The new tool head is the most compact and simplest version I've designed yet. In addition, to being much quicker and easier to print, it also features a much simpler magnetic couple between the tool head gantry and the hotend. It was challenging to devise a belt clamping mechanism in this new quite confined space, but I've got something that has been working well so far.

Open House 2018

Hydra Research invites you to come by our office for a behind the scenes look at what we do. We will have free drinks, snacks, and more! Bring your friends and family and explore the magic of 3D Printing and open source design.

LulzBot's Case Study Featuring Hydra Research

We are honored to be featured on LulzBot's website! We love LulzBot 3D printers and could not be happier that they reached out to us to showcase how we use their printers on their website. Long live open source :)

High Detail Resin 3D Printing

Hydra Research is excited to announce that we are adding high detail SLA resin 3D printing to our print service. SLA prints will be produced on the industry leading Form 2 by Formlabs.

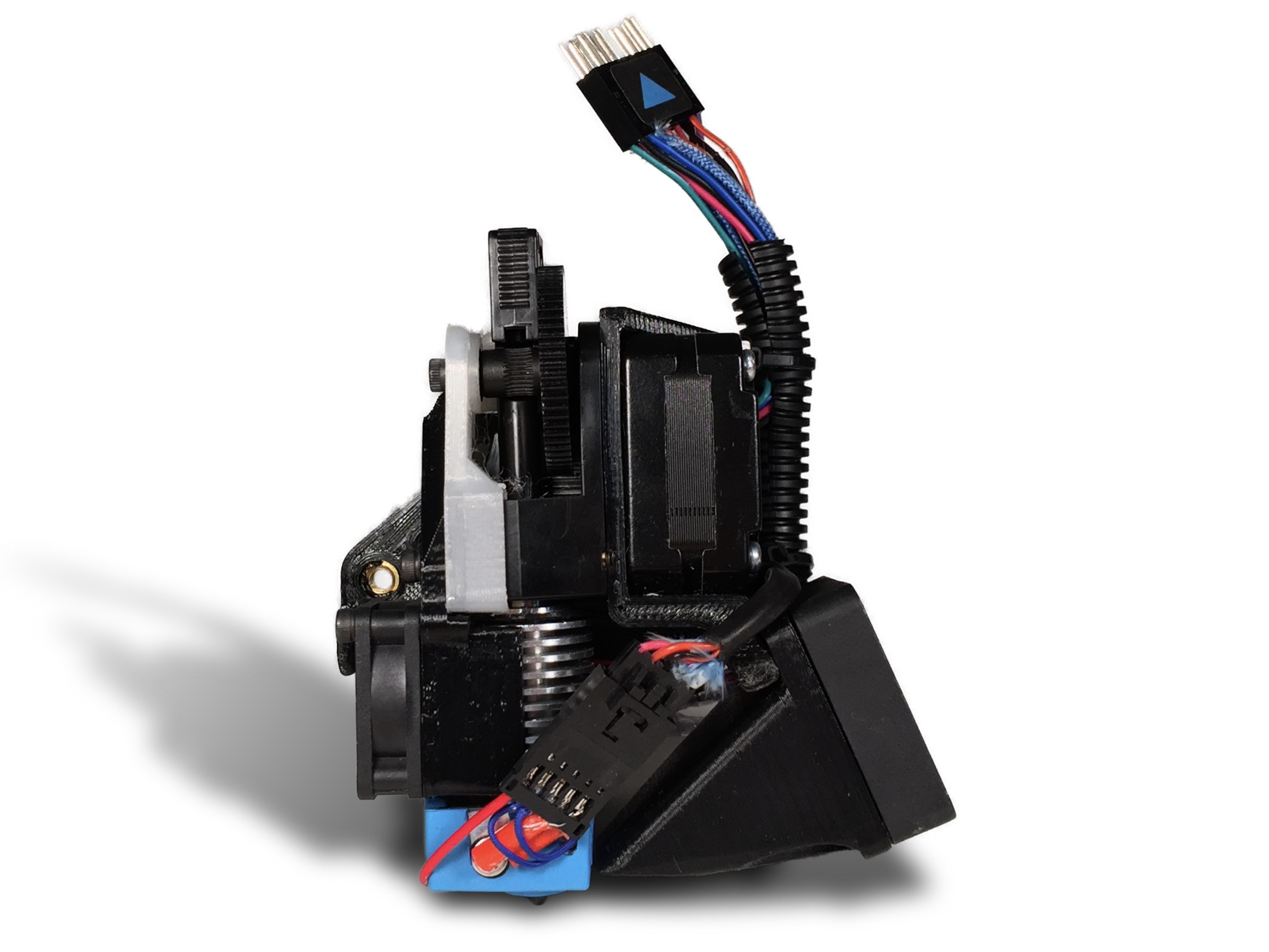

Introducing the LM Nano Tool Head for the LulzBot Mini 3D Printer

We here at Hydra Research are always looking for ways to streamline the efficiency and quality of the 3D printing experience. When we expanded our printer profile in late 2016 we had some frustration because our printers used different sized filaments 1.75mm and 2.85mm.